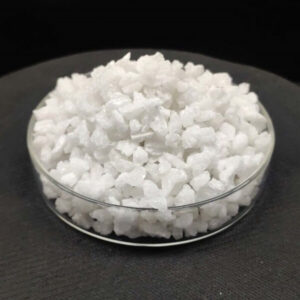

Low Sodium White Fused Alumina Product Details

| Item | Typical value | Guarantee value |

| Al2O3 | 99.6% | 99.3% |

| Fe2O3 | 0.05% | 0.10% |

| SiO2 | 0.08% | 0.15% |

| Na2O | 0.06% | 0.10% |

| Bulk density(g/cm3) | 3.55 min | |

| Micro size available | F240~F1500, JIS240~JIS4000#,P240~P2500 | |

| Abrasive grits size available | F24~F220 | |

| Refractory grain size available | 0-1, 1-3, 3-5mm, 200mesh, 325mesh | |

Low Sodium White Fused Alumina Production Process

- Raw materials: Using the high-grade low-sodium Bayer industrial alumina powder

- Mixing: mix low-sodium alumina raw materials with boric acid, ammonium chloride, aluminium fluoride and other additives, strictly by the formula ratio,

- Grinding: Add the mixed raw materials to a ceramic ball mill and grind for 2-4 hours

- Electric melting: Put the prepared mixed raw materials into the electric furnace, proceed high-temperature smelting during the temperature is strictly controlled at 2100℃-2300℃ degrees Celsius, the duration is 1-2 hours

- Cooling: Let the molten white fused alumina fully cool down, and use a specialised container to avoid contamination.

- Crushing: use a specialised crushing production line for processing, crushing and screening

- Washing: use the pure water from the water filtration workshop to wash or acid-pickling the semi-finished products to remove impurities, and finally dry