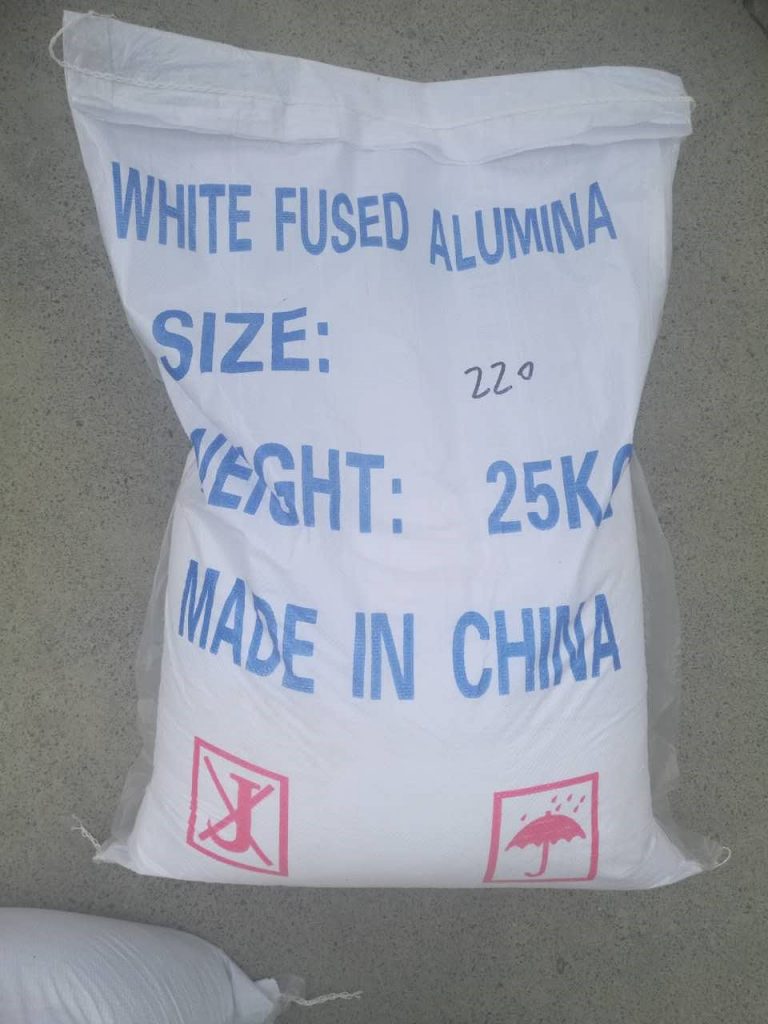

White Fused Alumina (WFA), specifically 60 mesh, is a very good and commonly used abrasive for blasting stainless steel when you need to achieve a specific, consistent finish without contamination.

Why 60 Mesh White Fused Alumina is Suitable for Stainless Steel

-

Contamination-Free (“White Metal” Finish): This is the primary reason for choosing WFA over brown aluminum oxide or slag abrasives. It is 99.5%+ pure aluminum oxide (Al₂O₃), containing no free iron or silica. This prevents embedment of impurities into the stainless steel surface, which is critical because embedded iron particles can lead to rust staining and corrosion (pitting), defeating the purpose of using stainless steel.

-

Angular & Sharp (60 Mesh):

-

Mesh Size: 60 mesh corresponds to a particle size of about 250 microns (0.010 inches). This is a medium-coarse grit.

-

Effect: It provides an aggressive cut for rapid cleaning and deburring, while leaving a defined, uniform anchor profile (typically in the range of 1.5 – 3 mils/38-75 µm Ra). This profile is excellent for promoting coating adhesion if painting or powder coating is the next step.

-

-

Reusability & Hardness: WFA is very hard (9.0 on the Mohs scale). It fractures to create new sharp edges, allowing for multiple reuses in a closed-loop blasting system, making it cost-effective over time.

Typical Applications on Stainless Steel

-

Surface Preparation for Coatings: Creating a perfect anchor profile for paint, powder coat, or PTFE coatings.

-

Weld Cleaning: Removing heat tint (oxidation scales), weld spatter, and smoothing weld beads.

-

Deburring: Removing sharp edges from machined or stamped parts.

-

Decorative Finishing: Producing a uniform, matte (satin) finish that is both aesthetic and functional. The 60 mesh will give a fairly coarse satin finish. For a finer satin look, you would move to 80, 100, or 120 mesh.

-

Cleaning & Restoration: Removing mill scale, light rust, old paint, or contaminants without damaging the base metal.

Comparison with Other Common Options for Stainless

| Abrasive | Pros for Stainless Steel | Cons for Stainless Steel | Best For |

|---|---|---|---|

| White Fused Alumina (60M) | Non-contaminating, sharp, reusable, consistent profile. | More expensive than slag. | All-purpose prep, weld cleaning, coating prep. |

| Glass Bead | Non-contaminating, produces a bright, peened finish, low profile. | Less aggressive, limited cutting power, not ideal for heavy rust/scale. | Decorative finishing, light cleaning, cosmetic satin finish. |

| Plastic Media | Non-damaging, removes coatings without altering the metal. | Very low cutting power, not for heavy duty cleaning. | Removing paint/coatings from delicate stainless parts. |

| Aluminum Silicate (Slag) | Very inexpensive, aggressive cut. | HIGH RISK OF IRON CONTAMINATION causing rust. Unacceptable for critical stainless applications. | Not recommended for stainless steel where corrosion resistance is key. |