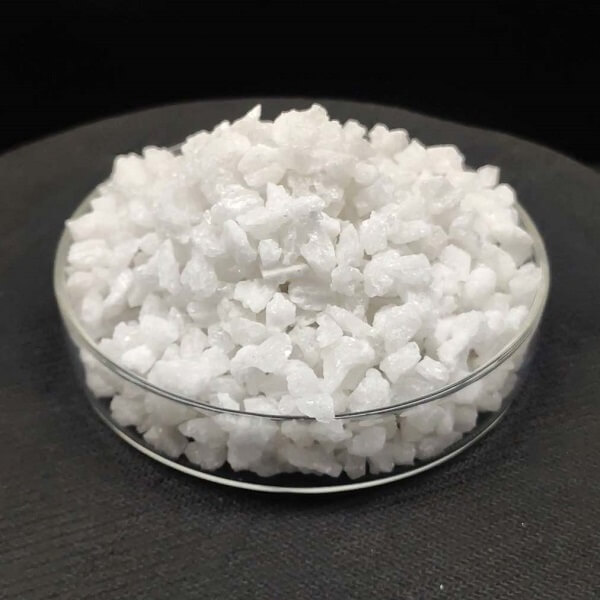

white fused alumina (WFA), its refractory properties are a major application area that leverages its core characteristics to the extreme.

Refractory Properties of White Fused Alumina

White fused alumina is a premier raw material in high-performance refractories due to its unique combination of properties, all stemming from its high purity and stable crystal structure.

| Property | Description & Rationale | Benefit in Refractories |

|---|---|---|

| 1. Very High Purity | Al₂O₃ content is typically ≥99%. Low levels of silica (SiO₂), iron oxide (Fe₂O₃), and other impurities. | – High Refractoriness Under Load (RUL): Impurities form low-melting glasses that soften at high temperatures. High purity resists this. – Excellent Corrosion Resistance: Fewer impurities mean fewer phases for slag, metal, or alkali vapors to attack. |

| 2. Extremely High Melting Point | The pure α-Al₂O₃ phase has a melting point of ~2050°C. | – Provides the fundamental high-temperature capability for linings in severe thermal environments (e.g., steel ladles, petrochemical furnaces). |

| 3. Excellent Volume Stability & Low Creep | The stable crystal structure has minimal permanent linear change on reheating (PLC) and resists deformation under constant load at high temperatures. | – Ensures the refractory lining maintains its structural integrity and does not shrink, crack, or collapse during service, leading to a longer campaign life. |

| 4. High Hardness & Abrasion Resistance | Mohs hardness of 9. | – Resists erosion from solid charges, particle-laden gases, and flowing molten materials (e.g., slag, metal). |

| 5. Good Thermal Shock Resistance | While not as good as some lower-expansion materials like silicon carbide, its moderate thermal expansion and high strength allow it to withstand a reasonable number of thermal cycles. | – Suitable for applications involving intermittent operation or rapid temperature changes, though this is often managed by the overall refractory formulation. |

| 6. Chemical Inertness | Highly resistant to attack by acids, slags, and oxidizing atmospheres. | – Key for corrosion resistance. It performs well against acidic slags and is often used in “slag-line” areas. (Note: It is less resistant to strong alkalis and reducing atmospheres). |

How WFA is Used in Refractory Products

WFA is not used alone but as a critical aggregate or grain component within a refractory matrix. Its properties define the backbone of the final product.

As an Aggregate Grain:

WFA is crushed and screened into various grain sizes (coarse, medium, fine).

These grains form the skeletal structure of the refractory, providing:

High-Temperature Strength

Abrasion and Erosion Resistance

Slag Penetration Resistance (due to low reactivity).

In Refractory Formulations:

Bricks and Shapes: Used in high-alumina bricks, mortars, and precast shapes for demanding applications.

Monolithics (Unformed Refractories): A key component in:

Low-cement and Ultra-low-cement Castables (LCC/ULCC): This is a primary application. The high purity and precise grading of WFA allow for dense, strong, and high-performance castable structures with minimal weak points (from the cement).

Gunning and Ramming Mixes: Used for rapid lining repair and installation.

Plastics and Moldables.

Key Application Areas in Industry

The properties of WFA make it ideal for the most severe conditions in various high-temperature industries:

Steel Industry:

Ladle Linings: Especially in the slag line area where corrosion is most aggressive.

Tundish Linings: For continuous casting.

Heating Furnace Hearths.

Petrochemical Industry:

Steam Crackers: In transfer line exchangers and radiant tubes where resistance to thermal shock and erosion from catalyst fines is critical.

Reformers and other high-temperature furnace linings.

Ceramic Industry:

Kiln Furniture: Used to make setters, posts, and saggers that hold ceramic ware during firing. Its high purity prevents contamination of the products.

Waste Incineration & Gasification:

Lining for chambers exposed to aggressive ash and slag.