1. The Role of White Aluminum Oxide in Foam Ceramics

Foam ceramics are highly porous, sponge-like structures used primarily as filters for molten metal (e.g., aluminum, iron, steel, copper). White aluminum oxide is the primary raw material, or aggregate, that forms the ceramic skeleton of this filter.

Its function is to create a rigid, three-dimensional network that:

Physically traps non-metallic inclusions (slag, oxides).

Chemically absorbs fine impurities through its surface.

Withstands extreme thermal shock when immersed in molten metal.

Resists erosion and dissolution by the molten metal.

2. Why White Aluminum Oxide is the Preferred Choice

Compared to other materials like brown fused alumina or silicon carbide, white aluminum oxide offers a superior combination of properties for this critical application:

| Property | Why It’s Important for Foam Ceramics | How White Alumina Excels |

|---|---|---|

| High Purity | Impurities can contaminate the molten metal. | Al₂O₃ content > 99.5%. Very low levels of silica (SiO₂), iron oxide (Fe₂O₃), and other fluxes. |

| High Refractoriness | Must remain solid and stable in molten metal (e.g., aluminum ~660°C, iron ~1500°C). | Extremely high melting point (~2050°C). |

| Excellent Chemical Inertness | Must not react with the molten metal being filtered. | Highly stable in molten aluminum and other non-ferrous metals. |

| Good Thermal Shock Resistance | Must not crack when plunged from room temperature into molten metal. | Its pure, crystalline structure provides good resistance to thermal stress. |

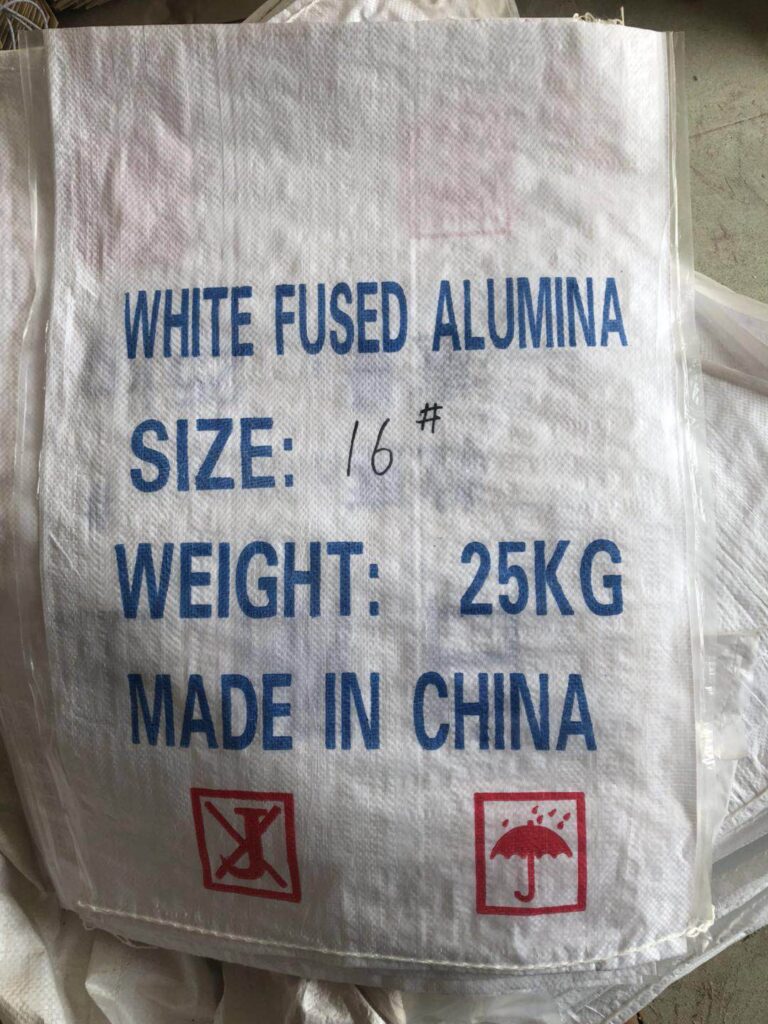

| Controlled Particle Size | Determines the slurry viscosity, coating thickness, and final filter strength. | Available in precisely graded particle size distributions. |

3. Key Specifications of the Powder

The alumina powder is not a single size but a carefully graded distribution of particles to ensure optimal properties in the final product.

- Purity: > 99.5% Al₂O₃ is standard. This minimizes the formation of low-temperature glassy phases that weaken the ceramic structure at high temperatures.

- Particle Size Distribution: A typical blend might include:

- Coarse grains: -40 mesh to -200 mesh (e.g., 100-400 microns). These form the main structural skeleton.

- Fine flour: -325 mesh (< 44 microns). These fine particles fill the gaps between the coarse grains, promoting densification during sintering and increasing the final strength of the filter.

- Chemistry: Low Soda (Na₂O) content is critical, as it acts as a flux and severely degrades the high-temperature properties.