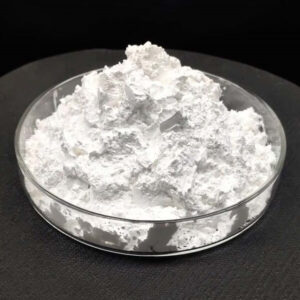

White aluminum oxide is white with the main crystal phase alpha-Al2O3,it is made from the high quality alumina by melting above 2200℃ in the electric arc furnace and cooling.

White aluminum oxide produced in titling electric arc furnace has the advantage of high bulk density and low porosity and the volume stability and thermal shock resistance can be improved.

Physical and Chemical Composition of JIS400# White aluminum oxide micropowder for polishing:

Physical Properties | |

Hardness: micro | 21600-22600kg/mm3 |

Hardness: Mohs | 9.0 min |

Specific Gravity | 3.95-3.97g/cm3 |

Bulk Density | 1.65-2.05g/cm3 |

Particle Shape | Blocky, Sharp |

Color | white |

Chemical compositions | |

Al2O3 | 99.40min |

SiO2 | 0.15max |

Na2O | 0.28max |

Fe2O3 | 0.06max |

CaO | 0.03max |

size distribution of 400#White Fused Alumina Micro Powder:

ITEM | D0(um) | D3(um) | D50(um) | D94(um) |

#240 | <127 | <103 | 57.0±3.0 | >40 |

#280 | <112 | <87 | 48.0±3.0 | >33 |

#320 | <98 | <74 | 40.0±2.5 | >27 |

#360 | <86 | <66 | 35.0±2.0 | >23 |

#400 | <75 | <58 | 30.0±2.0 | >20 |

Applications of JIS400# White aluminum oxide powder for polishing:

polishing and lapping for precise polishing

Raw material for Whetstone, oil stone

Wear resistant coating material

Ceramic membrane filters material

Surface Preparation and Finishing:

One of the primary applications of white fused alumina powder lies in surface preparation and finishing. In

Precision Grinding and Cutting:

In precision manufacturing, where accuracy is paramount, white fused alumina powder finds extensive use in grinding and cutting applications. Its hardness and abrasive properties make it an ideal choice for shaping and refining high-precision components in industries ranging from electronics to medical devices. T

Bonded Abrasive Tools:

White fused alumina powder serves as a fundamental component in the production of bonded abrasive tools such as grinding wheels, sharpening stones, and abrasive belts.

Lapping and Polishing:

Industries requiring high levels of surface flatness and optical clarity, such as semiconductor manufacturing and optical lens production, rely on white fused alumina powder for lapping and polishing purposes.

Ceramic Manufacturing:

White fused alumina powder plays a crucial role in the production of refractory materials and advanced ceramics due to its high melting point, thermal stability, and chemical inertness.