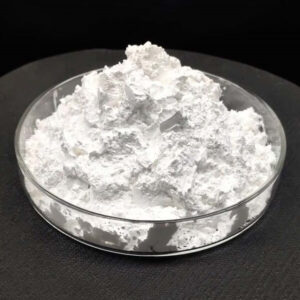

White Fused Alumina (WFA) is obtained from the fusion of high purity alumina in electric arc furnaces. WFA is raw material characterized with high hardness, yet friable with high purity, chemical stability, a high melting point, and large crystal size. White Fused Alumina is used in many applications including grinding and cut off wheels, refractories and ceramic shapes, coated abrasives, investment casting shells, laminates, coatings, blasting abrasives, lapping and polishing, and many many more.

| MODEL: F400 | |

| Al2O3 | ≥99.3% |

| SiO2 | ≤0.04 |

| NaO2 | ≤0.3 |

| Fe2O3 | ≤0.05 |

| K2O | ≤0.01 |

Typical physical properties | |

Hardness: | Mohs:9.0 |

Maximum service temperature: | 1900 ℃ |

Melting Point: | 2250 ℃ |

Specific Gravity: | 3.95g/cm3 |

Volume density | 3.6g/cm3 |

Bulk density(LPD): | 1.75-1.95 g/cm3 |

Color: | White |

Particle shape: | Angular |

Application of white aluminum oxide :

Surface Preparation and Finishing:

One of the primary applications of white fused alumina powder lies in surface preparation and finishing.

Precision Grinding and Cutting:

In precision manufacturing, where accuracy is paramount, white fused alumina powder finds extensive use in grinding and cutting applications. Its hardness and abrasive properties make it an ideal choice for shaping and refining high-precision components

Bonded Abrasive Tools:

White fused alumina powder serves as a fundamental component in the production of bonded abrasive tools such as grinding wheels, sharpening stones

Lapping and Polishing:

Industries requiring high levels of surface flatness and optical clarity, such as semiconductor manufacturing and optical lens production, rely on white fused alumina powder for lapping and polishing purposes

Refractory and Ceramic Manufacturing:

White fused alumina powder plays a crucial role in the production of refractory materials and advanced ceramics due to its high melting point, thermal stability, and chemical inertness.

Products showroom:

Production line