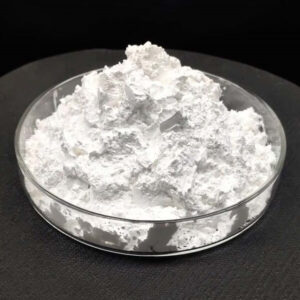

White Aluminum Oxide abrasive is used in a wide variety of industries including: automotive, aircraft, medical, dental, cosmetic and flooring. Obtained from the fusion of calcined alumina in electric arc furnaces, this sharp, fast-cutting, very hard abrasive is effective in media blasting, cleaning, glass etching and surface preparation. In the cosmetics industry, Microdermabrasion Crystals are used for exfoliation creams and skin treatments.

| Typical Chemical composition | |

| AL2O3 | 99.3%min |

| SiO2 | 0.06% |

| Na2O | 0.3%max |

| Fe2O3 | 0.05%max |

| CaO | 0.04%max |

| MgO | 0.01%max |

| K2O | 0.02#max |

| Typical physical properties | |

| Hardness: | Mohs:9.0 |

| Maximum service temperature: | 1900 ℃ |

| Melting Point: | 2250 ℃ |

| Specific Gravity: | 3.95g/cm3 |

| Volume density | 3.6g/cm3 |

| Bulk density(LPD): | 1.75-1.95 g/cm3 |

| Color: | White |

| Particle shape: | Angular |

| Available size: | |

| FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 |

| JIS | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# 10000# |

| ITEM | D0(um) | D3(um) | D50(um) | D94(um) |

| #240 | <127 | <103 | 57.0±3.0 | >40 |

| #280 | <112 | <87 | 48.0±3.0 | >33 |

| #320 | <98 | <74 | 40.0±2.5 | >27 |

| #360 | <86 | <66 | 35.0±2.0 | >23 |

| #400 | <75 | <58 | 30.0±2.0 | >20 |

| #500 | <63 | <50 | 25.0±2.0 | >16 |

| #600 | <53 | <41 | 20.0±1.5 | >13 |

| #700 | <45 | <37 | 17.0±1.5 | >11 |

| #800 | <38 | <31 | 14.0±1.0 | >9.0 |

| #1000 | <32 | <27 | 11.5.±1.0 | >7.0 |

| #1200 | <27 | <23 | 9.5±0.8 | >5.5 |

| #1500 | <23 | <20 | 8.0±0.6 | >4.5 |

| #2000 | <19 | <17 | 6.7±0.6 | >4.0 |

| #2500 | <16 | <14 | 5.5±0.5 | >3.0 |

| #3000 | <13 | <11 | 4.0±0.5 | >2.0 |

| #4000 | <11 | <8.0 | 3.0±0.4 | >1.8 |

| #6000 | <8.0 | <5.0 | 2.0±0.4 | >0.8 |

| #8000 | <6.0 | 3.5 | 1.2±0.3 | >0.6 |

Surface Preparation and Finishing:

One of the primary applications of white fused alumina powder lies in surface preparation and finishing. Industries such as automotive, aerospace, and metal fabrication rely on this abrasive for tasks like deburring, polishing, and surface cleaning. leaving surfaces impeccably smooth and ready for subsequent treatments such as coating or painting.

Precision Grinding and Cutting:

In precision manufacturing, where accuracy is paramount, white fused alumina powder finds extensive use in grinding and cutting applications. Its hardness and abrasive properties make it an ideal choice for shaping and refining high-precision components in industries ranging from electronics to medical devices.

Lapping and Polishing:

Industries requiring high levels of surface flatness and optical clarity, such as semiconductor manufacturing and optical lens production, rely on white fused alumina powder for lapping and polishing purposes. The fine particles facilitate the removal of surface imperfections with exceptional precision, resulting in mirror-like finishes essential for advanced optical and electronic applications.