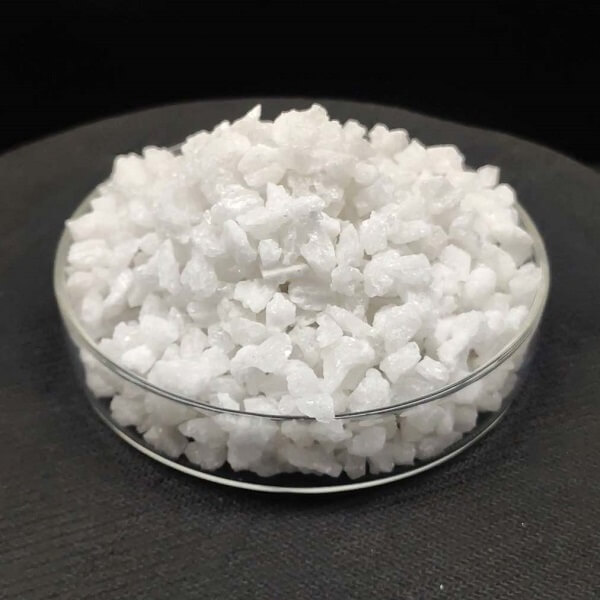

What is White Fused Alumina?

White fused alumina is a synthetic, ultra-pure mineral produced by fusing high-purity alumina (Al₂O₃) in an electric arc furnace at temperatures over 2000°C. The starting material is typically calcined alumina, a powder derived from bauxite via the Bayer process.

The “white” designation comes from its high purity (typically 99.0% to 99.5% Al₂O3), which gives it a white or crystalline appearance, distinguishing it from brown fused alumina (which contains impurities like silica and titania).

Key Properties as a Refractory Material

WFA’s value in refractory applications stems from its exceptional combination of physical and chemical properties:

-

High Purity & Chemical Inertness:

-

With minimal impurities (low SiO₂, Fe₂O₃, etc.), it is highly resistant to attack by slags, acids, and alkalis. This makes it stable in harsh chemical environments.

-

-

High Refractoriness:

-

It has an extremely high melting point of approximately 2050°C. This allows it to withstand very high service temperatures without softening or deforming.

-

-

Excellent Mechanical Strength & Hardness:

-

WFA is very hard (9 on the Mohs scale, just below diamond). This gives refractories made from it high cold crushing strength and excellent resistance to abrasion and erosion.

-

-

Good Volume Stability:

-

It has a low thermal expansion coefficient and does not undergo phase transformations that cause significant volume changes upon repeated heating and cooling. This results in excellent thermal shock resistance and spalling resistance.

-

-

Controlled Porosity (in shaped products):

-

When used as an aggregate in bricks and castables, it allows for the formulation of dense, strong refractory structures with optimized porosity for performance.

-

Physical and Chemical Composition

| Physical Properties | |

| Hardness: micro | 21600-22600kg/mm3 |

| Hardness: Mohs | 9.0 min |

| Specific Gravity | 3.95-3.97g/cm3 |

| Bulk Density | 1.65-2.05g/cm3 |

| Particle Shape | Blocky, Sharp |

| Color | white |

| Chemical compositions | |

| Al2O3 | 99.40min |

| SiO2 | 0.15max |

| Na2O | 0.28max |

| Fe2O3 | 0.06max |

| CaO | 0.03max |

| Fraction sand or powder | |

| Grit designation | Passing rate % |

| 0-1mm | 90 |

| 1-3mm | 90 |

| 3-5mm | 90 |

| 100 mesh | 90 |

| 200 mesh | 90 |

| 320 mesh | 90 |

How is it Used in Refractories?

WFA is rarely used as a monolithic block. Instead, it is processed into various forms and used as the primary aggregate or grain in refractory products.

1. Refractory Grains & Powders

This is the most common form. WFA is crushed, screened, and milled into a precise range of particle sizes:

-

Coarse Aggregates: (e.g., 0-1mm, 1-3mm, 3-5mm) form the structural skeleton of shaped and unshaped refractories.

-

Fine Powders: (e.g., -200 mesh, -325 mesh) fill the voids between coarse aggregates, creating a dense matrix.

-

Flour/Micro-powders: Used in advanced ceramics and high-performance castables.

2. Shaped Refractories (Bricks and Shapes)

WFA grains are mixed with binders (and sometimes other additives) and pressed into bricks or special shapes, which are then fired at high temperatures.

-

WFA Bricks: Used in the most critical areas of high-temperature furnaces.

3. Unshaped (Monolithic) Refractories

These are installed on-site without pre-firing. WFA is the key aggregate in:

-

Castables: Dry mixtures that are mixed with water and poured/vibrated into place.

-

Plastics: Moldable, clay-like materials rammed into place.

-

Gunning Mixes: Spray-applied mixes for lining or repairing furnaces.

-

Ramming Mixes: Used for compacting in specific areas like furnace bottoms.

Common Applications

Due to its superior properties, WFA refractories are used in the most demanding high-temperature industrial processes:

-

Steel Industry:

-

Ladle linings (especially working linings).

-

Slide gate plates and well blocks.

-

Tundish linings and furniture.

-

Areas in electric arc furnaces and blast furnaces exposed to severe abrasion.

-

-

Petrochemical Industry:

-

Lining of catalytic cracking units in oil refineries.

-

Reformers and other high-temperature reactors.

-

-

Ceramic & Glass Industry:

-

Kiln furniture (shelves, setters) for firing technical ceramics, sanitaryware, and porcelain.

-

Checkers and regenerators in glass melting furnaces.

-

Lining of glass tanks.

-

-

Non-Ferrous Metals:

-

Linings for aluminum holding and melting furnaces.

-

Furnaces for processing copper, zinc, and other metals.

-

-

Cement & Lime Industry:

-

Burning zone and transition zone linings in rotary kilns.

-

-

Incinerators & Waste-to-Energy Plants:

-

Withstands corrosive flue gases and abrasive ashes.

-