What are Refractories?

First, a quick definition: Refractories are materials that can withstand extremely high temperatures (typically > 1000°C or 1832°F) and harsh conditions (abrasion, chemical corrosion, thermal shock) without melting or degrading. They are the linings for furnaces, kilns, incinerators, reactors, and other high-temperature processing equipment.

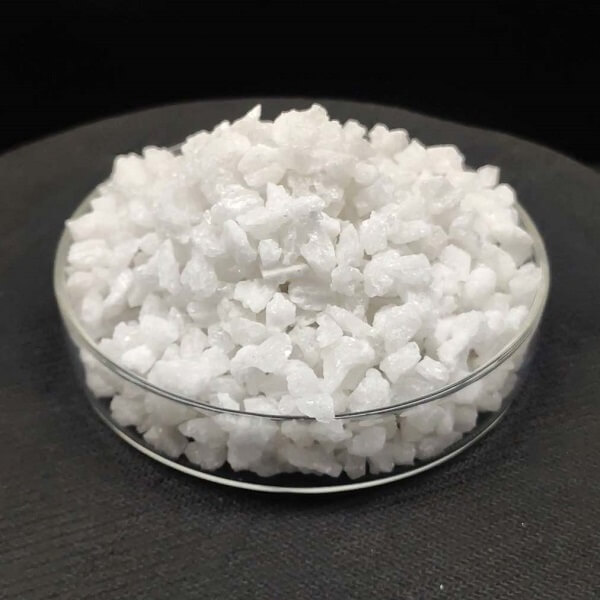

Why White Fused Alumina is an Excellent Refractory Material

White Fused Alumina is not just a refractory material; it’s often considered a high-performance or premium choice for critical applications. The reasons are a direct consequence of its chemistry and manufacturing process.

1. Extremely High Purity and Chemical Inertness

-

High Al₂O₃ Content: WFA typically contains >99% Alumina (Al₂O₃). This is its single most important property for refractories.

-

Near-Neutral Behavior: Alumina is chemically stable and acts as an amphoteric oxide, but in high-purity form, it is highly resistant to attack by both acidic and basic slags (within certain limits), making it versatile.

-

Low Impurities: Impurities like SiO₂, Fe₂O₃, and Na₂O are present in very low quantities (often <0.5%). These impurities form low-melting-point phases (e.g., glassy phases). Their absence in WFA means:

-

Higher Hot Strength: The refractory maintains its structural integrity at higher temperatures.

-

Better Creep Resistance: It is more resistant to slow deformation under load at high temperatures.

-

Reduced Corrosion: Fewer reactive sites for slags, molten metals, and gases to attack.

-

2. Very High Melting Point

-

The melting point of pure Alumina is 2050°C (3722°F). WFA, being nearly pure, has a melting point very close to this. This defines its Pyrometric Cone Equivalent (PCE)—a measure of its refractoriness—as being very high, allowing it to be used in the most extreme temperature environments.

3. Excellent Mechanical Properties at High Temperature

-

High Hot MOR (Modulus of Rupture): WFA-based refractories retain their strength even when they are glowing hot. This is crucial for withstanding mechanical abuse, load-bearing, and abrasive conditions inside a furnace.

-

Outstanding Abrasion Resistance: As with coatings, its Mohs hardness of 9 makes it ideal for areas subject to mechanical wear, such as kiln car tops, burner blocks, and areas where charge material is constantly moving.

4. Good Volume Stability (Re-firing Shrinkage)

-

Because WFA is already a fused product, it has undergone its most dramatic phase change and shrinkage during its own manufacturing. When used as an aggregate in shaped refractories (bricks) or monolithics (castables), it contributes to excellent dimensional stability upon first heating, minimizing the risk of cracking during the dry-out of a new lining.

Common Forms and Applications of WFA in Refractories

WFA is rarely used alone. It is a key ingredient, or “aggregate,” within a refractory matrix.

1. Shaped Refractories (Bricks and Shapes)

-

WFA is graded into specific particle sizes (coarse, medium, fine) and bonded with other high-purity materials or ceramic bonds to press into bricks.

-

Applications: Lining for high-temperature furnaces (e.g., tunnel kilns, shuttle kilns), steel ladles, cement kiln transition zones, and critical areas in chemical processing reactors.

2. Monolithic Refractories (Unformed)

This is the largest and most growing application area.

-

Castables: WFA aggregates are mixed with calcium aluminate cement and fine powders. When water is added, it can be poured, pumped, or vibrated into place to form a seamless lining.

-

Gunning Mixes: Similar to castables but designed to be sprayed (gunned) onto a surface for rapid repair or installation.

-

Ramming Mixes: A drier mix rammed into place for specific applications.

-

Applications: Complex furnace linings, ladle linings, burner blocks, cyclones, and any area where a joint-free, custom-shaped lining is required.

3. Specialty Products

-

Investment Casting Shells: The high refractoriness and purity of WFA flour (fine powder) make it an excellent stucco and backup material for creating ceramic molds to cast superalloy turbine blades and other precision metal parts.

-

Kiln Furniture: Posts, setters, and slabs made from WFA can be used to support ceramic ware during firing at very high temperatures due to their strength and resistance to sagging (creep).

Comparison with Brown Fused Alumina (BFA) in Refractories

| Property | White Fused Alumina (WFA) | Brown Fused Alumina (BFA) |

|---|---|---|

| Al₂O₃ Content | >99% | ~95-97% |

| Impurities | Very Low (Na₂O, etc.) | Higher (SiO₂, TiO₂, Fe₂O₃) |

| Refractoriness | Higher (closer to 2050°C) | Slightly Lower |

| High-Temperature Strength/Creep | Superior | Good, but not as good as WFA |

| Cost | Higher | More Economical |

| Typical Use | Critical, high-temperature applications where purity and performance are paramount. |