To remove mineral deposits, rust, fouling, scale, and other buildup from steam turbines, the ALOX (aluminum oxide), glass beads and garnet sand is the most effectively abrasives.

In order to improve the efficiency of the steam turbines blade, the turbine needs to be thoroughly cleaned to remove stubborn deposits that accumulate on its surface and components

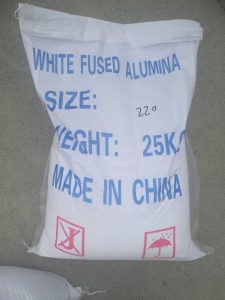

Aluminum Oxide Blasting (white aluminum oxide & brown aluminum oxide)

white aluminum oxide F120 F220 is the suitable abrasives for removing stubborn mineral deposits on steam turbines. white aluminum oxide mohs hardness is 9.0 and it can remove the dust effectively and make the apperace perfect. chemical compositon and phyaical properties are as below:

| Physical properties | Chemical compositions | Content (%) | |

| Crystal body | Hexagonal | Al2O3 | ≥99.2 |

| Main crystal body | Al2O3 | ||

| Color | white | Na2O | ≤0.3 |

| True density | ≥3.9 g/cm3 | ||

| Bulk density | 1.75-1.95 g/cm3 | SiO2 | ≤0.1 |

| Mons’ hardness | 9 | ||

| Linear expansion coefficient | 8.3×10-4 | Fe2O3 | ≤0.05 |

Other Abrasive Blasting for steam turbines blade blasting

For a more aggressive form of blasting, or where a deeper profiling of the surface is desired, alternatives include garnet and glass beads, which can be used in different formulations, depending on the application and the need for dust control.

Turbine Parts Cleaned

- Rotors

- Blade Carriers

- Diaphragms

- Valve Components

- More etc…